VAS: Value added services is a process guided flow offered by SAP EWM for specific operations which needs to be done prior shipping/moving goods out of the warehouse or during putaway. Specific work centers are defined for VAS where this activity takes place, this can involve kitting, reverse kitting, simple VAS.

VAS customers are charged additionally for these operations and hence comes the need to manage finances, labor and quantity of additional packaging material which has been used in the process. This blog is a guide on how to set-up simple inbound VAS flow.

Business Case: Automobile manufacturer receive material in boxes/pallets as exception and has to oil and repack the parts in ready to use KLT boxes before being stored in warehouse. Enterprise owner wants automatic process for this putaway condition and uses SAP EWM to manage warehouse.

Areas covered in the blog:

1. Packaging specification creation and determination procedure.

2. Automatic VAS order creation for VAS relevant inbound material from specific vendor(ship from party).

3. VAS work center setup and execution inside it.

4. Movement flow setup and execution for VAS relevant material via storage process (POSC) .

Configuration Details

- PACKSPEC Config (Materials to be used in VAS)

- Choose a valid group for packspec.

- In details choose relevant condition.

- Make sure you see product page in contents

- Give your packaging mat (KLT box in this case)

- In the external step Give the POSC step where the packspec will be realised.

- Activate the packspec

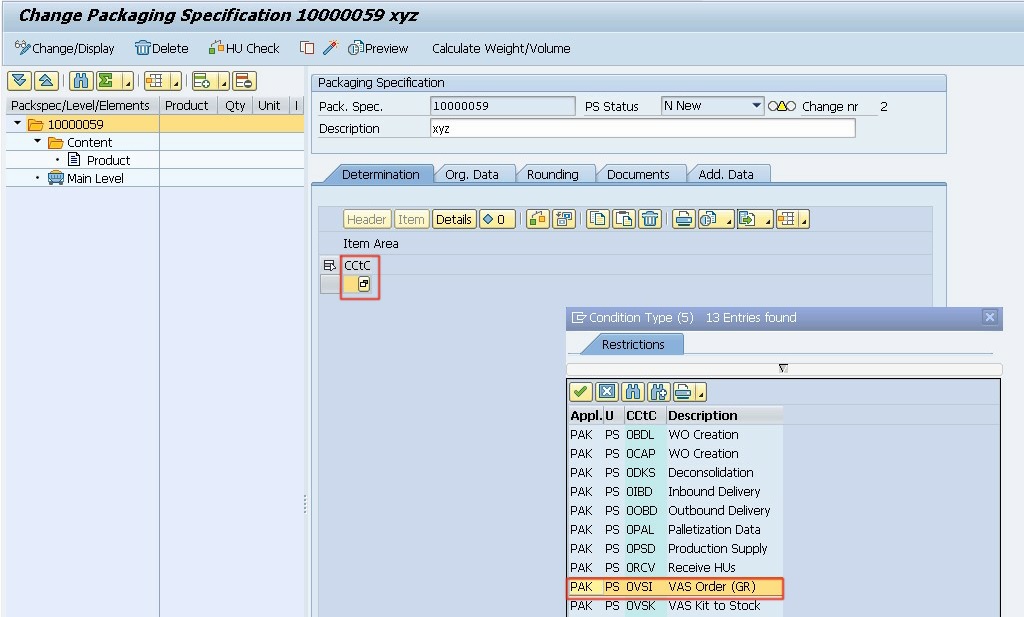

Choose valid condition type while creating packaging specifications. You can configure these in master data for packspecs in EWM customizing IMG

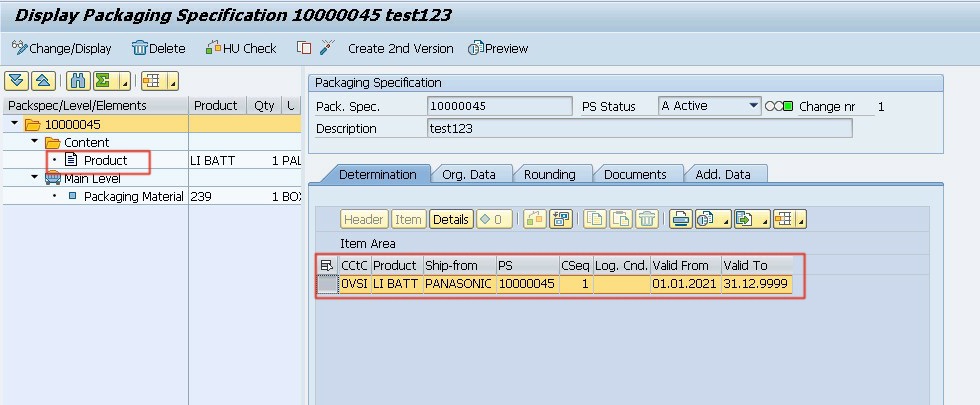

In contents maintain VAS relevant product, do not miss the mandatory fields required by CCtC which will be used in PACKSPEC determination. (Marked in red ticks)

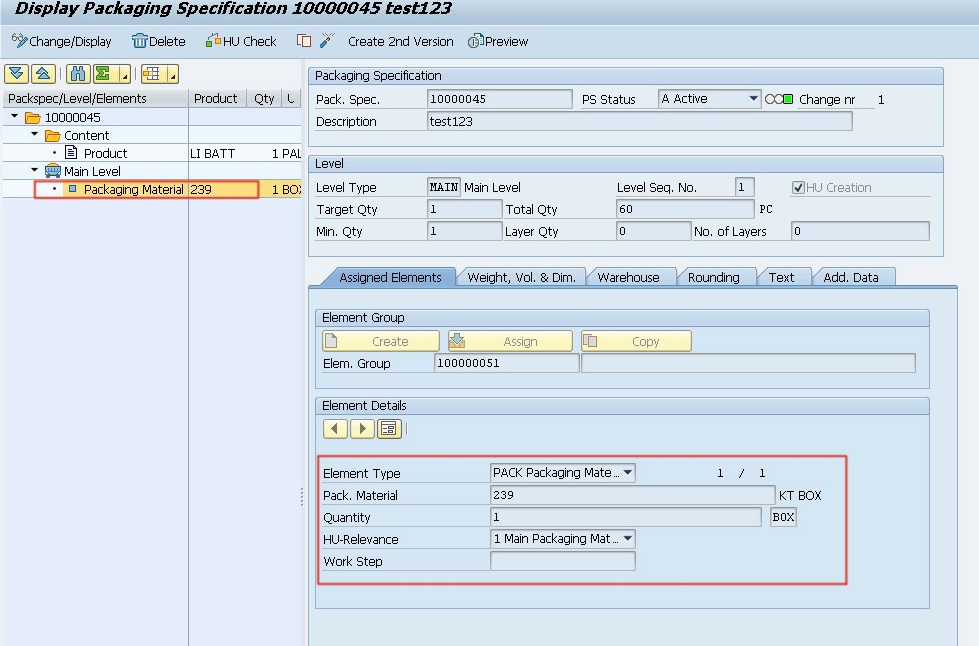

In the Main level maintain your packaging material and quantities.

Assign element group or create one and give element types as Main/Auxiliary.

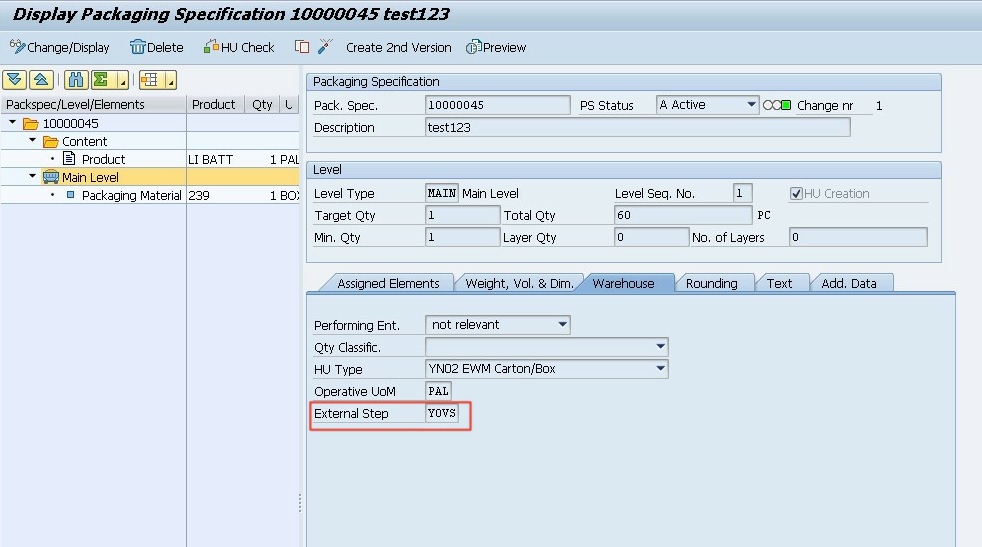

Assign appropriate VAS process step in warehouse tab, this is the external step from POSC.

This is discussed in detail in later config steps.

2. VAS Order Creation customization

PATH – SCM Extended Warehouse Management – Extended Warehouse Management – Cross-Process Settings -Value-added Services (VAS)

- Make sure you have number ranges maintained for VAS orders. (Mandatory Step) Without it you will not be able to create VAS order document even manually.

- Make sure you have activated order document management. (Mandatory Step) Without it you will not be able to create VAS order document even manually.

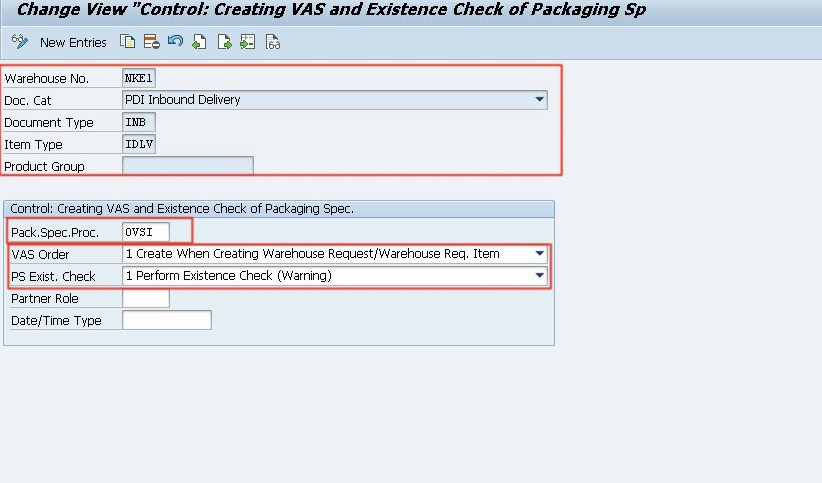

- In the VAS relevance settings for VAS define for what document type, item type you want to create VAS order for and procedure used for packspec determination, when you want to create the VAS order(At the time of WH request) also describe what to do when system do not find packspec. Also specify the partner role from which we are receiving the delivery.

Procedure used for determination of PACKSPEC is key link between packaging specs and VAS Activity.

Step – 3

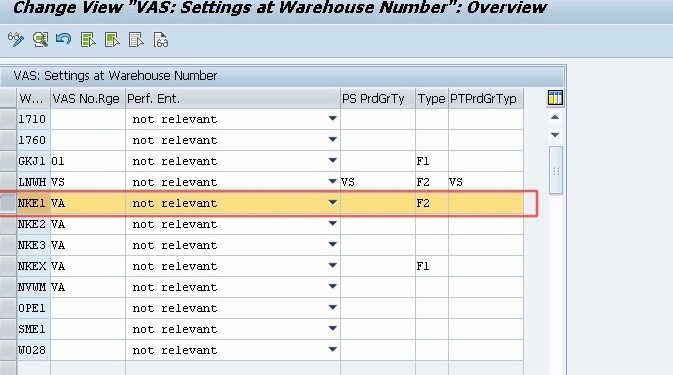

4. In Warehouse number dependent settings define the stock type and performing entity also along side that describe the product type group and number range to be used.

Step 4

3. POSC Configuration

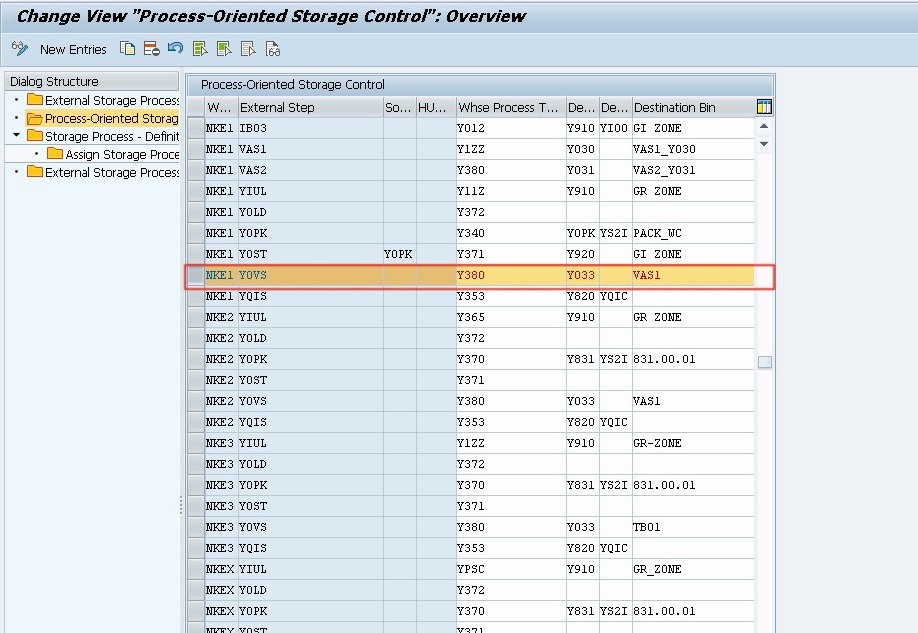

- Define POSC to use storage control. In our process we defined 1 VAS step and One putaway step.

- Make sure you have relevant bins in Storage types for work center and final putaway.

- Make sure you activate automatic task creation in for final putaway.

POSC Definition of VAS process step. (Same as entered in packspec)

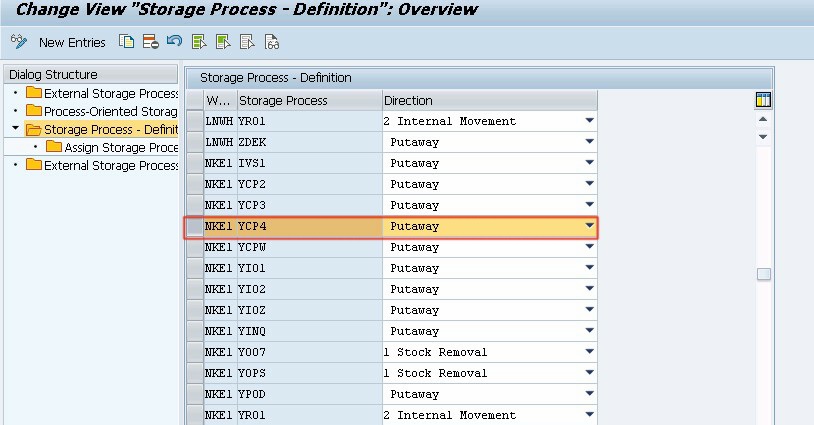

Define Storage Process definition

Assign Process Steps to Storage Process

(Make sure you have checked automatic task creation flag)

Define WPT and assign Storage Process and source bin

4. Work Center Configuration

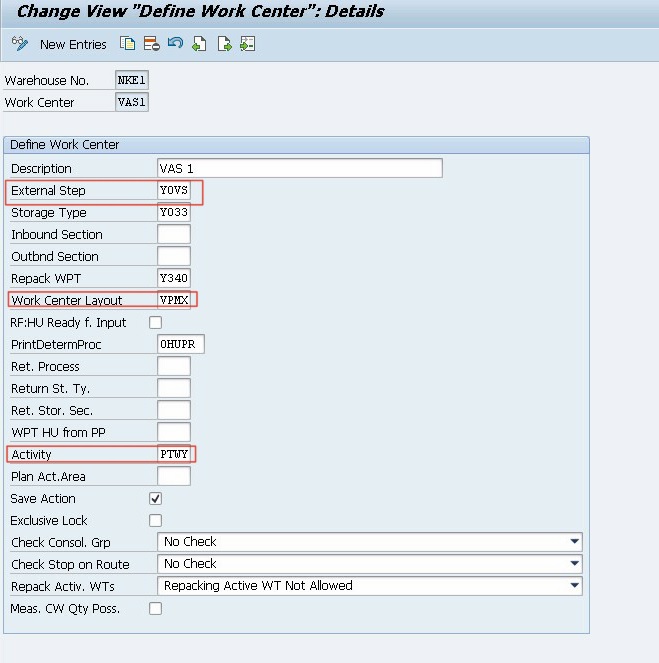

- Choose standard VAS work center layout or customize as per need.

- Create a VAS work center for your activities.

- Specify the POSC step in work center definition.

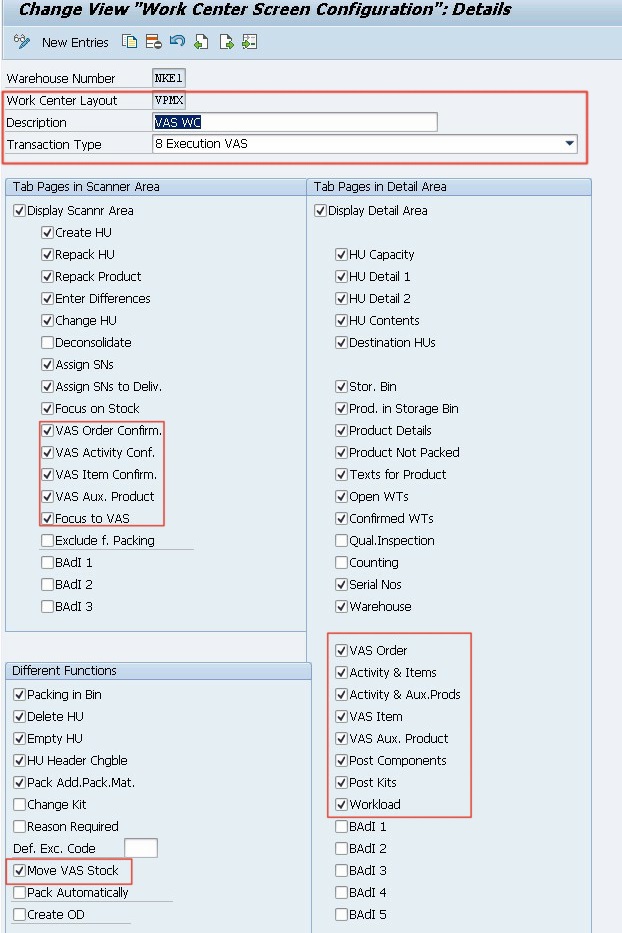

Defining work center layout

(Make sure your layout have VAS relevant activity controls)

Define work center – Step 2 and 3

VAS work center

Execution Supplements

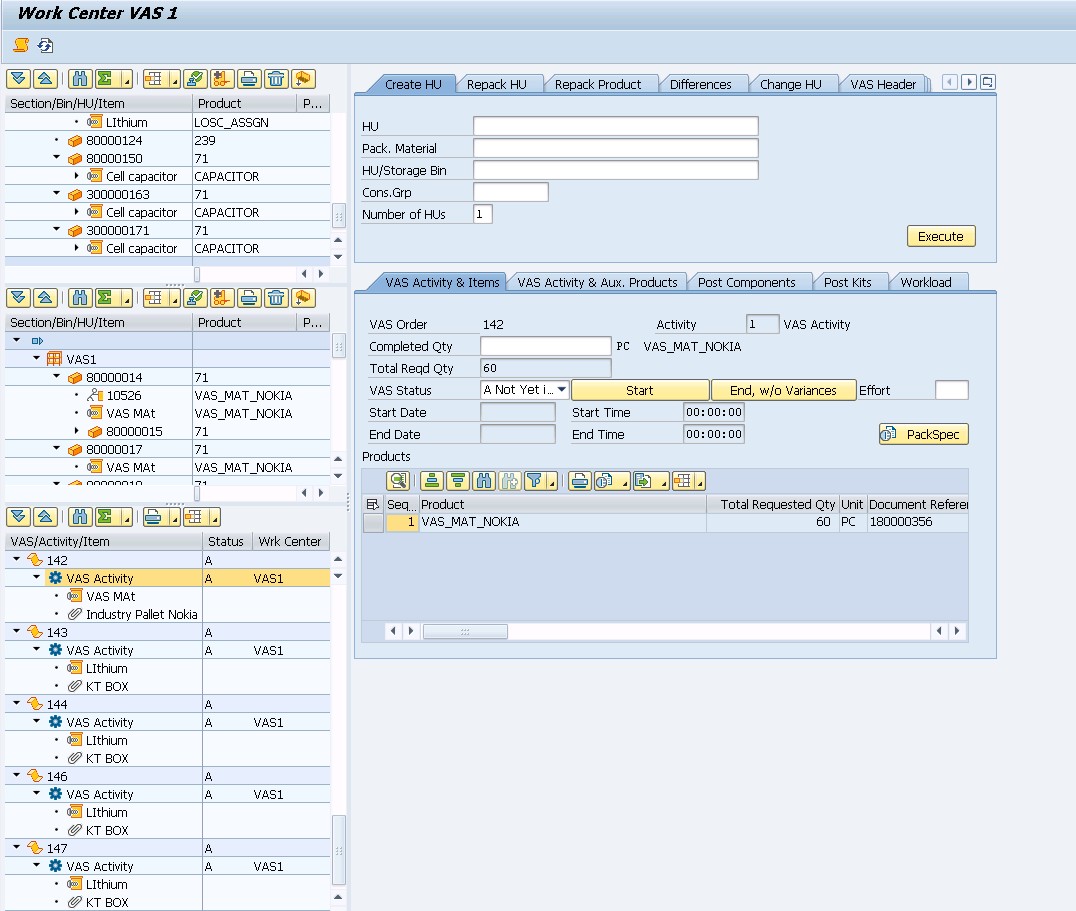

T-code for VAS work center – /scwm/vasexec

T-code for viewing VAS order – /scwm/vas_i

T-code for packspec creation- /scwm/packspec

Execution

Flow

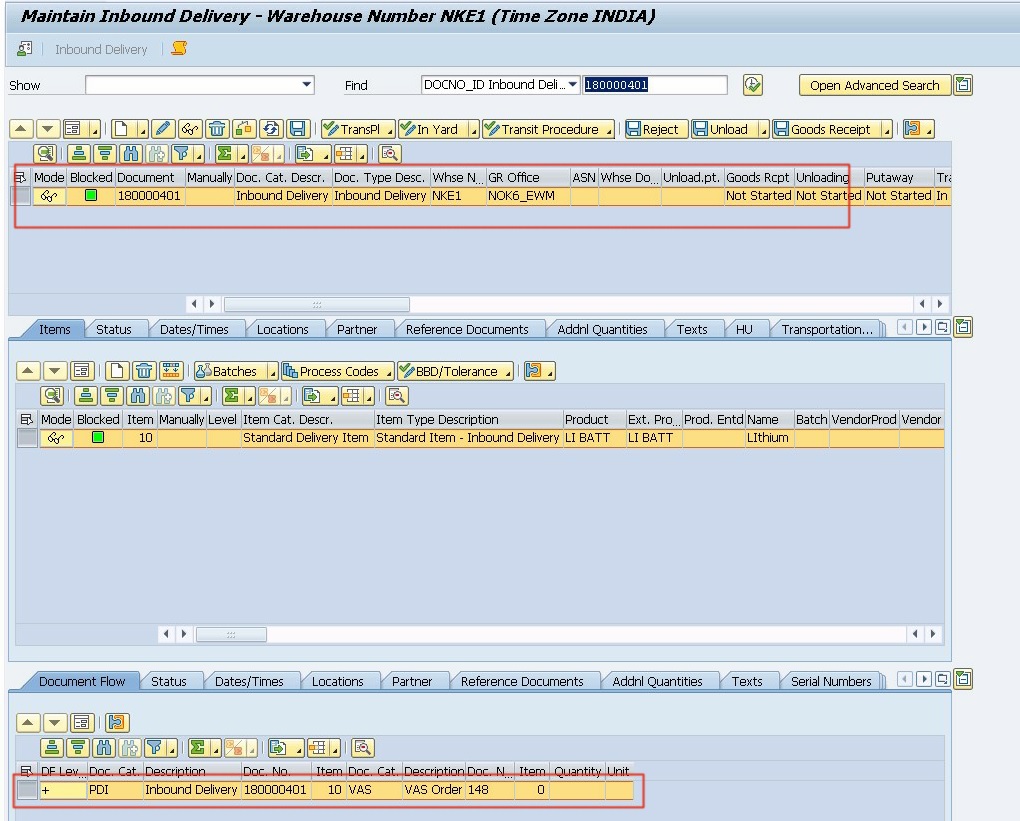

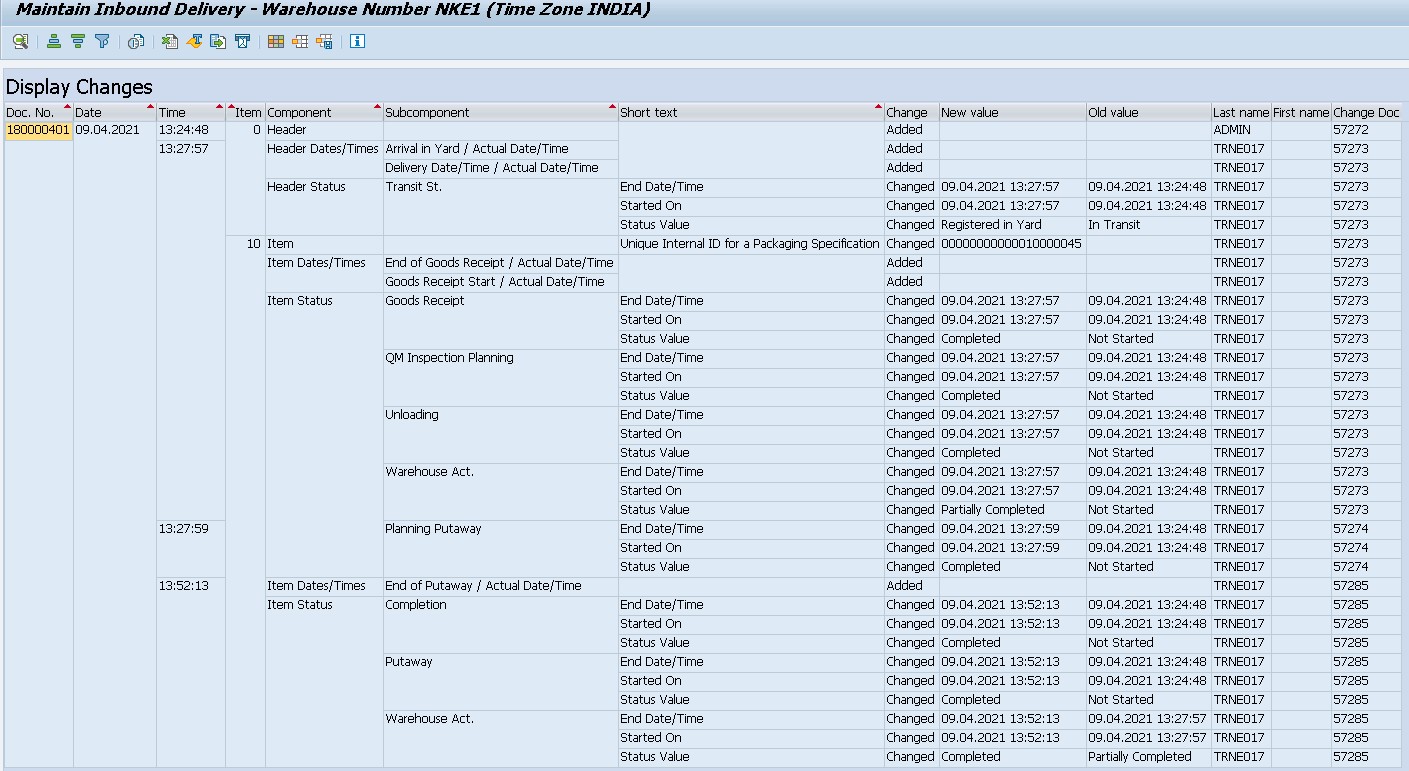

- Receive inbound delivery request in EWM. (A VAS order must have been generated for current customization)

- Delivery comes packed from vendor.

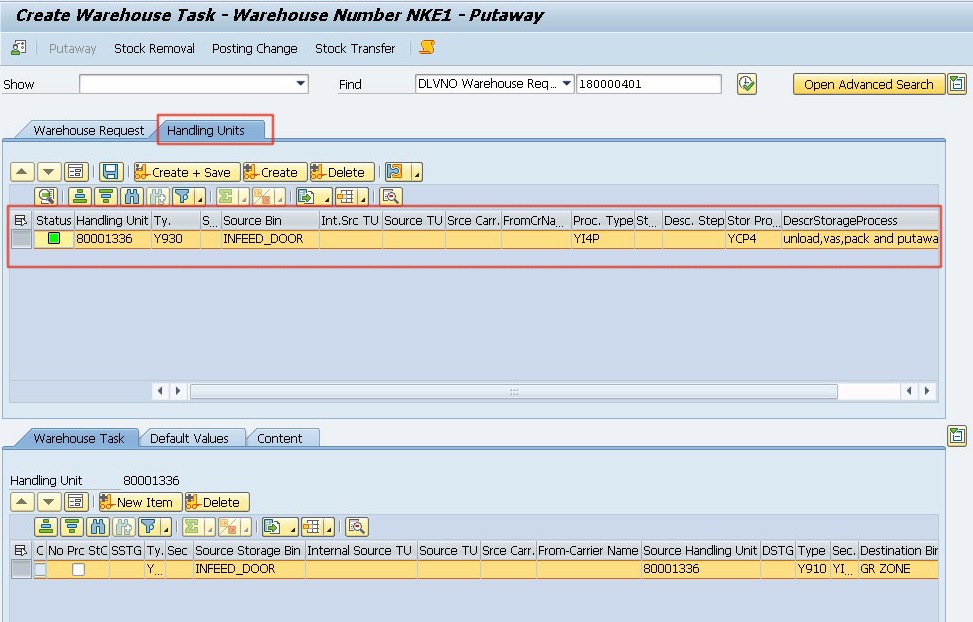

- Create 1st task. From warehouse door to inbound staging area where goods receipt is done.

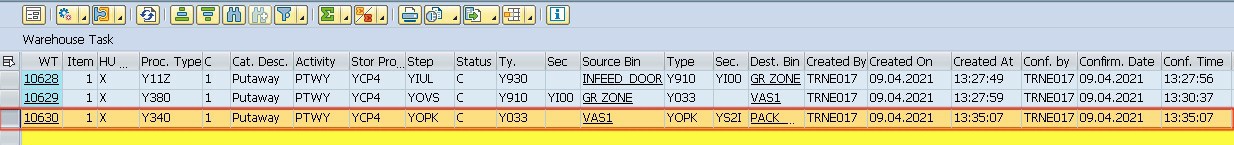

- Confirm task – (Infeed_Door -> GR Zone)

- Now second task which is automatically triggered by system takes the goods from staging area to VAS work center where we are required to use KLT boxes and do the oiling of parts.

Confirm second task (Gr Zone -> VAS1) - Complete VAS activity in VAS work center and then complete HU step in VAS work center.(This would create a WT from VAS work center -> Pack work center )

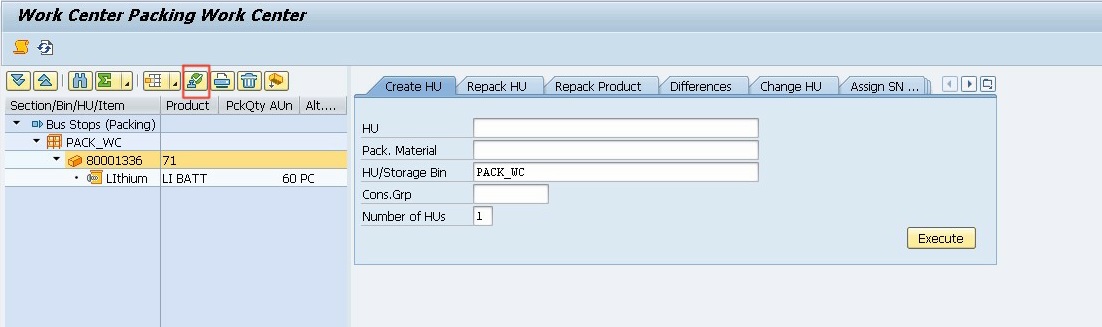

- Now you will be required to do additional packing like clubbing of KLT boxes on one HU(Handling Unit) in packing work center. Then complete the HU process step in packing work center.

- Confirm the task created.

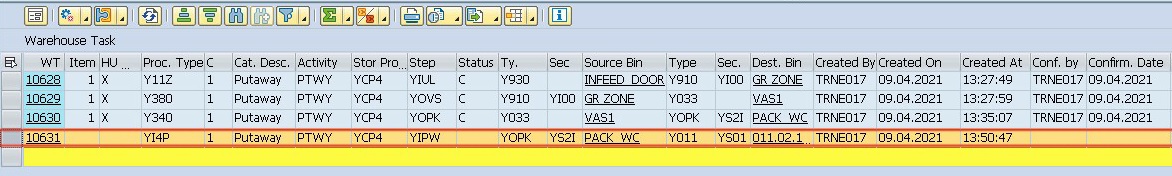

- Final open warehouse task for putaway in “narrow aisle” storage type will be created. Confirm goods movement. (Pack_WC –> Final Bin)

- For the final step system uses search sequence for determining the final destination bin.

In Execution we will see this process working in a 4 step POSC with our associated delivery , HU movements for VAS relevant product.

Step 1. Create inbound delivery in ECC

Step 2. Receive inbound del request in EWM. (Make sure you get the VAS order created automatically)

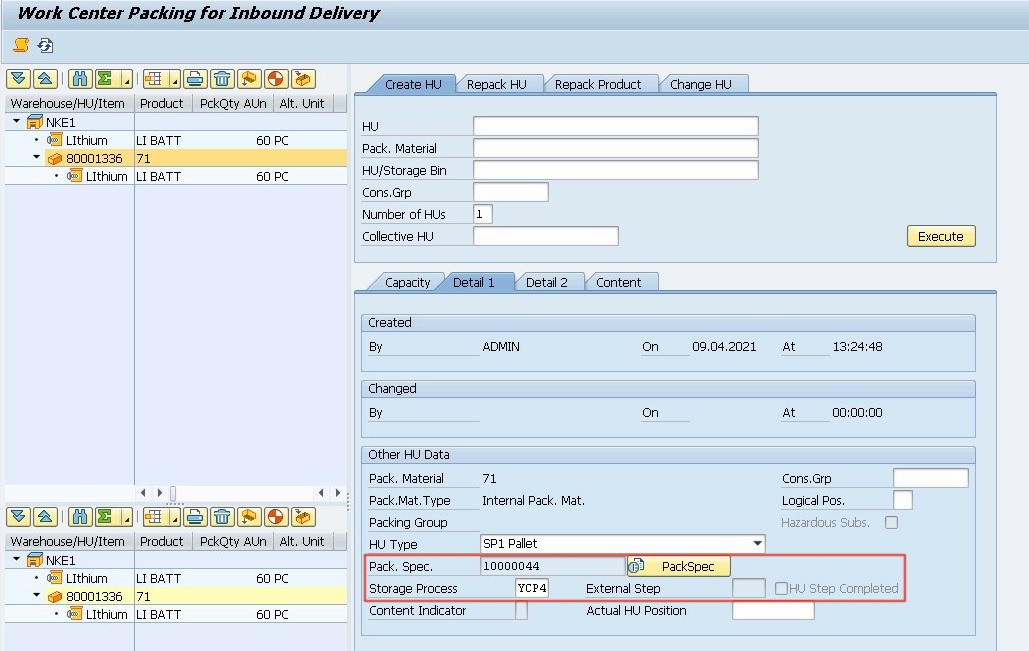

Step 3 . Pack the product (mandatory).

Note : This packspec is different from the one used for VAS . In our case the product comes packed automatically by the use of packspec highlighted above.

Step 4. Create first WT and confirm it.

In monitor subsequent open WT will appear automatically for concerned IBD, confirm it to take the product to VAS WC

Step 5. Confirm second task triggered by POSC to move the stock to VAS WC

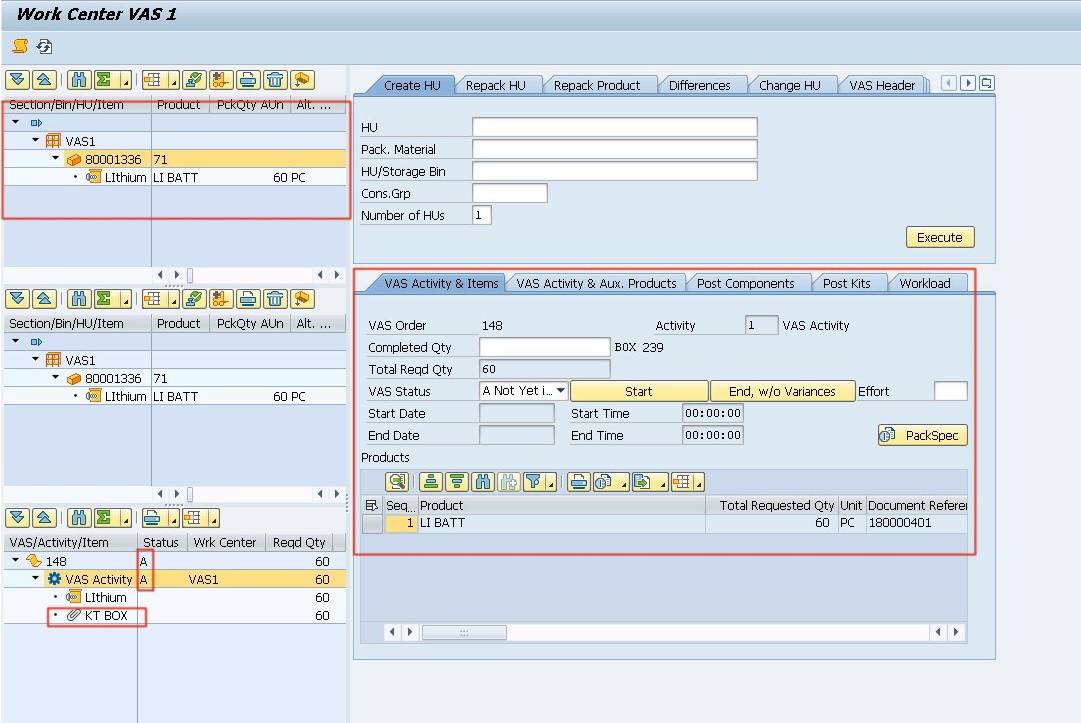

Step 6. Go to VAS work center. T code /SCWM/VASEXEC

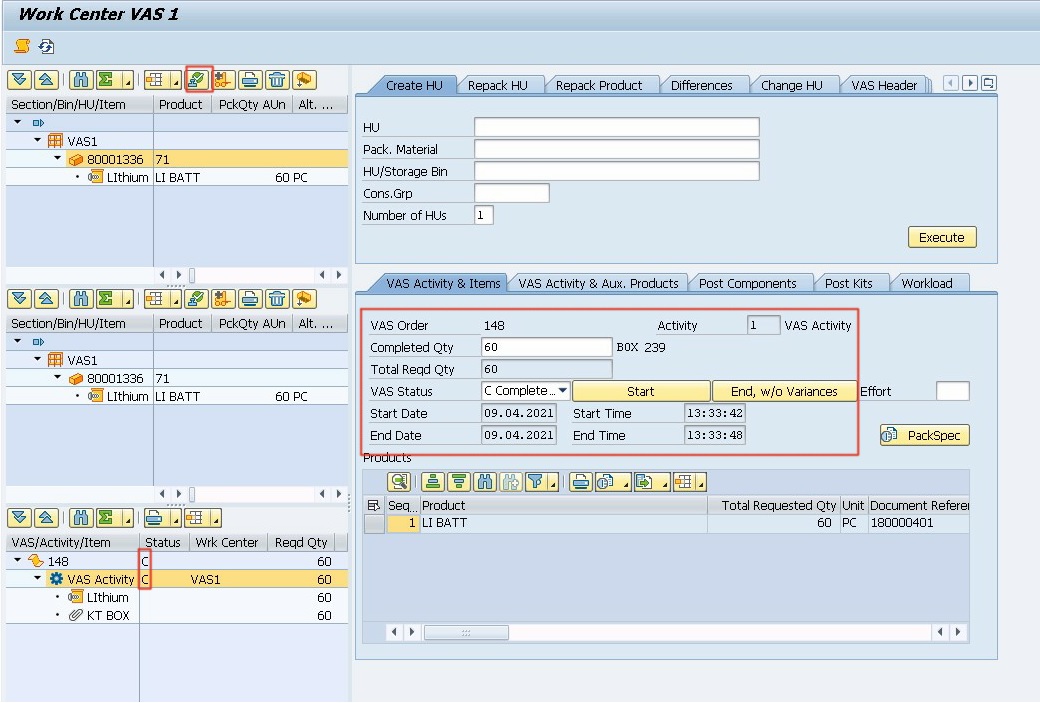

Step 7. Complete VAS activity for the concerned VAS order for the product. Notice the change in VAS order status from A-C.

Complete the HU putaway step in VAS work center.

Step 8. Go to monitor to see following WT triggered by POSC.

Step 9. Complete the HU putaway step in packing work center.

Step 10. Confirm open product WT which will appear finally in the monitor for final putaway step. The WTs in order represent goods movement as described in the flow step above 4th 5th 6th 9th.

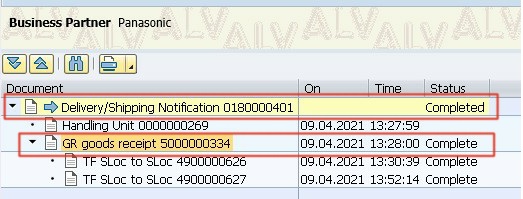

Step 11. Check if the automatic GR is posted by PPF in EWM

Step 12. Check for updated delivery document flow in ECC

Conclusion : You can set up automatically trigger VAS order creation for simple inbound deliveries from product and ship-from as the two key fields. VAS process keeps track of the material used for value addition and labor cost per UoM. VAS order creation triggers are same for all the different standard VAS processes like kit to stock or reverse kitting.

NOTE : This is a made up example with all custom data, it do not communicate process or system details of an actual enterprise.

Stay tuned for Kit-To Stock VAS process which is from business point of view much more interesting as well as useful for production plants in general.

Comment (1)

Thanks for sharing the blog, its really informative.